Improve Industrial Storage Efficiency

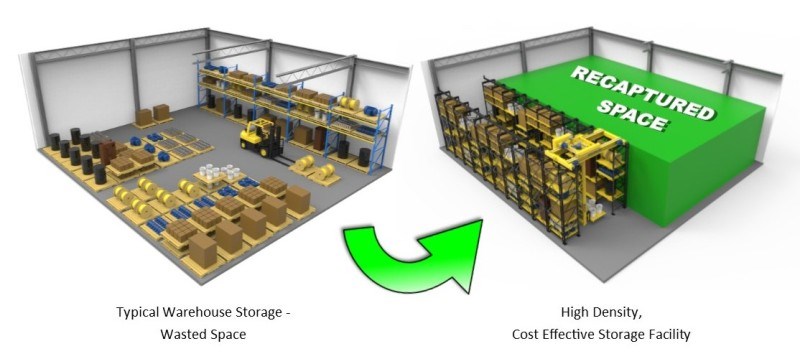

REDUCE YOUR STORAGE FOOTPRINT BY 50%

Get in touch to learn more..

Increase productivity. Maximize storage density by minimizing unused vertical space within racking with adjustable racking system.

CALL: (905) 279-1275 | sales@swissinstruments.com

Rapistak Product Line

A diverse array of solutions tailored to the requirements of industrial, commercial, automotive, governmental, military, and various other sectors.

RAPISTAK Storage Management System

Capacities of 2000, 4000, 6000 lbs., Rack heights from 8 ft. to 25 ft.

- Savespace by matching asset size to appropriately sized pallets

- A dedicated lifting device helps to minimize forklift dependence

- Substantially reduced aisle widths compared to conventional forklift turning radius

- Instant adjustability allows greater pallet density and a reduced storage footprint

THE STORAGE AND RETRIEVAL OF HEAVY, BULKY ITEMS HAS NEVER BEEN EASIER!

Based on a system of dynamically adjustable pallets (rather than fixed shelves) and a captive lifting and handling device, the STAK System® helps maximize storage density by minimizing the vertical space requirements of each stored pallet and its contents.

STAK System®: ARS — Adjustable Racking System

A completely flexible heavy-duty storage solution, the ARS Adjustable Racking System allows super-efficient storage of items of varying size and weight. Like the STAK System®, the ARS is based on a system of removable, positionable pallets, but does not include the STAK System’s mast and bridge assembly. ARS pallets are moved by means of fork trucks.

Industrial Racking & Warehouse Shelving

Industrial racking and warehouse shelving systems are the backbone of efficient storage operations. They organize inventory, optimize space, increase throughput, and make material handling safer and more productive for facilities of all sizes.

At Swisso Storage, we offer a full range of industrial racking solutions — from heavy-duty pallet racks to adjustable shelving — designed to meet the demands of warehouses, commercial facilities, manufacturing plants, and logistics centers across North America.

What Are Industrial Racking & Warehouse Shelving Systems?

Industrial racking systems are engineered structures made of steel beams, uprights, and accessories that support stored goods, pallets, and components. These systems are designed to maximize both vertical and horizontal space in a facility while providing clear access, safety, and organization.

Warehouse shelving refers to smaller storage units that hold bins, small parts, tools, cartons, and lightweight inventory. Shelving systems can be standalone or integrated with larger racking structures for flexible inventory management.

Who Uses Industrial Racking?

Industrial racking and shelving systems are used across a wide range of industries:

- Manufacturing & Assembly Facilities — organize components and production materials

- Logistics & Distribution Centers — streamline order fulfillment

- Automotive & Aerospace — store parts with precision and traceability

- Retail and E-Commerce Warehouses — maximize storage for seasonal inventory

- Food & Beverage Storage — apply specialized racking compatible with hygiene standards

Why Industrial Racking Matters?

Maximize Storage Density

Industrial racking systems like adjustable pallet racks and STAK Systems help businesses store more inventory in less space by utilizing vertical heights and reducing unused floor area. This can reduce your storage footprint by up to 50% or more compared to conventional layouts.

Enhance Organizational Efficiency

Proper racking and shelving allow goods to be stored logically and accessed quickly. Clear labeling, organized bays, and structured storage minimize time spent searching for products and reduce picking errors.

Improve Workplace Safety

Stable racking structures protect inventory and people by preventing collapse, reducing cluttered aisles, and ensuring safe load distribution. Guardrails, column protectors, and proper anchoring increase safety in busy warehouse environments.

Easy Customization & Reconfiguration

Adjustable industrial shelving allows you to adapt your storage layout as needs evolve. Shelves can be moved up or down, expanded, or accessorized with drawers and dividers to organize different inventory sizes — from bolts to boxed units.

Common Types of Industrial Racking

Pallet Racking Systems

Pallet rack solutions support heavy loads and are the most common form of high-capacity warehouse storage. They allow pallets to be stacked vertically and accessed by forklifts or material handling equipment.

Types include:

- Selective Pallet Racking — direct access to every pallet

- Double-Deep Racking — increase density with two pallets deep

- Drive-in/Drive-Thru Racking — high-density storage ideal for bulk goods

- Cantilever Racking — ideal for long or bulky items like pipes and timber

Adjustable & Heavy-Duty Shelving

Heavy-duty shelving systems support various inventory types and can be reconfigured without entirely redesigning a layout. Shelving units are ideal for smaller parts, boxed inventory, and tools.

STAK & Adjustable Racking Systems

Systems like the STAK and ARS Adjustable Racking System use positionable pallets and ergonomic handling devices to improve pallet density and reduce reliance on forklifts, optimizing space and operator productivity.

HEAVY-DUTY STRENGTH

Roll-formed columns provide double-strength rest hooks on 7-3/4" centers. Pallets are reinforced with double-layer steel surfaces.

HIGH WEIGHT CAPACITY

Heavy-duty columns provide 25,000 lb. capacity per storage section (seismic zones 1 and 2).

PALLET FORK GUIDES

Ensure proper engagement and provide additional structural support. Opposing cross members offer total surface support stability.

SAFE AND ACCURATE RETRIEVAL

Simple, intuitive positioning allows the operator to relocate a pallet quickly, accurately and safely.

Frequently Asked Questions

What’s the difference between shelving and pallet racking?

Shelving is typically used for smaller, hand-accessible inventory and can be easily reconfigured, while pallet racking supports mezzanine-level storage and heavy pallet loads requiring forklifts.

Can racking systems integrate with warehouse management software?

Yes — advanced racking layouts can be supported by warehouse management systems for real-time inventory tracking and workflow optimization.

How do I choose the right industrial racking solution?

Consider inventory type, load weights, aisle width, building height, and workflow needs. Swisso Storage provides expert guidance to find the best fit for your operation.

How Swisso Storage Helps

At Swisso Storage, we are dedicated to helping businesses solve storage challenges with robust, flexible, and scalable systems:

- Custom Designed Solutions matched to your facility’s height, weight requirements, and workflow

- High-Strength Materials built for heavy loads and daily operations

- Modular Racking & Shelving that grows with your inventory

- Professional Consultation & Support from design to installation

Whether you need pallet racking, adjustable shelving, or complete storage system planning, Swisso Storage delivers solutions that balance efficiency, safety, and operational performance.

ADJUSTABLE RACKING SYSTEM ACCESSORIES

Choose the accessories you need to make your STAK System® or adjustable racking system work for you – whether you work with bulky spare parts, motors, dies, pumps, tires, computer equipment, or 55-gallon drums.

Store more with this dynamic, pallet-based storage and handling system – no forklift required. Unique handling device is completely ergonomic, easing the removal of even the largest loads.

Ready to Optimize Your Warehouse?

Industrial storage systems are essential to modern operations that care about productivity, safety, and scalability. Contact Swisso Storage to assess your needs and design a solution that matches your facility’s goals.